|

Torich International Co.,Ltd.

|

EN10297-1 mechanical steel tubing

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Seamless circular steel tubes for mechanical and general engineering purposes - Technical delivery conditions

Non-alloy and alloy steel tubes

Application: seamless round tubes which are made of non-alloy and alloy steels for mechanical and gneral engineering purposes.

Size range: O.D.: 6-168mm W.T.: 1-30mm L:max12000mm

Standard:EN10297-1

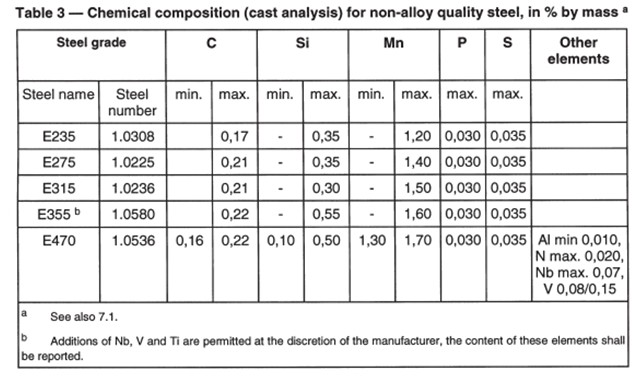

| Chemical composition | ||||||||||||||||

| Steel grade | C | Si | Mn | P | S | Cr | Mo | Ni | Other elements | |||||||

| Steel name | Steel number | min | max | min | max | min | max | max | max | min | max | min | max | min | max | |

| E235 | 1.0308 | 0.17 | - | 0.35 | - | 1.20 | 0.030 | 0.035 | ||||||||

| E275 | 1.0225 | 0.21 | - | 0.35 | - | 1.40 | 0.030 | 0.035 | ||||||||

| E315 | 1.0236 | 0.21 | - | 0.30 | - | 1.50 | 0.030 | 0.035 | ||||||||

| E355 b | 1.0580 | 0.22 | - | 0.55 | - | 1.60 | 0.030 | 0.035 | ||||||||

| E470 | 1.0536 | 0.16 | 0.22 | 0.10 | 0.50 | 1.30 | 1.70 | 0.030 | 0.035 | Al min 0.010, N max. 0.020, Nb Max.0.07, V 0.08/0.15 | ||||||

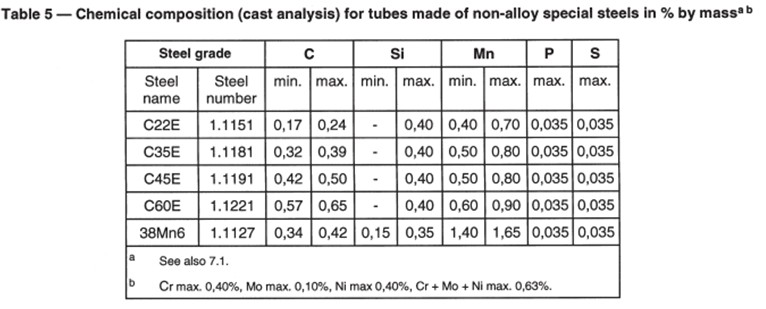

| C22E | 1.1151 | 0.17 | 0.24 | - | 0.40 | 0.40 | 0.70 | 0.035 | 0.035 | |||||||

| C35E | 1.1181 | 0.32 | 0.39 | - | 0.40 | 0.50 | 0.80 | 0.035 | 0.035 | |||||||

| C45E | 1.1191 | 0.42 | 0.50 | - | 0.40 | 0.50 | 0.80 | 0.035 | 0.035 | |||||||

| C60E | 1.1221 | 0.57 | 0.65 | - | 0.40 | 0.60 | 0.90 | 0.035 | 0.035 | |||||||

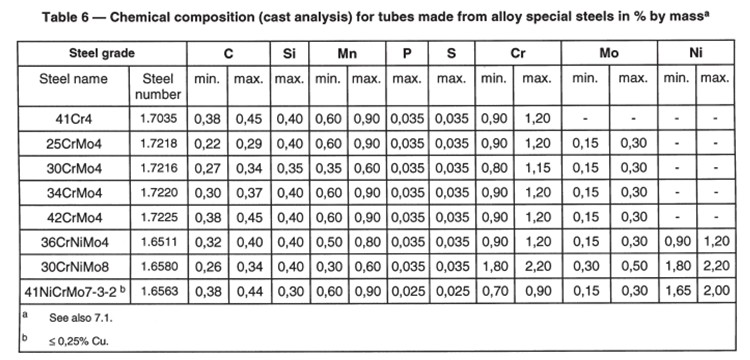

| 25CrMo4 | 1.7218 | 0.22 | 0.29 | 0.40 | 0.60 | 0.90 | 0.035 | 0.035 | 0.90 | 1.20 | 0.15 | 0.30 | - | - | ||

| 30CrMo4 | 1.7216 | 0.27 | 0.34 | 0.35 | 0.35 | 0.60 | 0.035 | 0.035 | 0.80 | 1.15 | 0.15 | 0.30 | - | - | ||

| 34CrMo4 | 1.7220 | 0.30 | 0.37 | 0.40 | 0.60 | 0.90 | 0.035 | 0.035 | 0.90 | 1.20 | 0.15 | 0.30 | - | - | ||

| 42CrMo4 | 1.7225 | 0.38 | 0.45 | 0.40 | 0.60 | 0.90 | 0.035 | 0.035 | 0.90 | 1.20 | 0.15 | 0.30 | - | - | ||

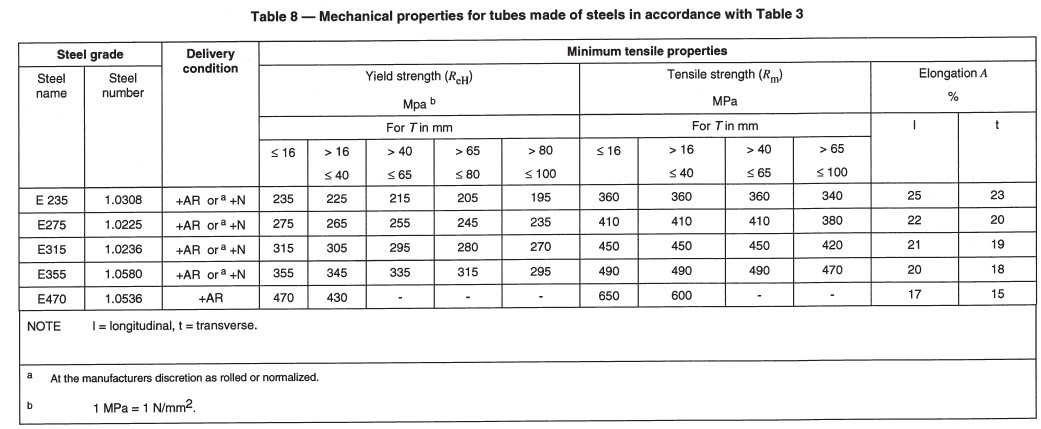

| Mechanical properties | |||||||||||||

| Steel Grade | Delivery conditiion | Minimum tensile properties | |||||||||||

| Steel name | Steel number | Yield strength(ReH) Mpa b | Tensile strength(Rm) Mpa | Elongation A % | |||||||||

| For T in mm | For T in mm | l | t | ||||||||||

| ≤16 | >16 | >40 | >65 | >80 | ≤16 | >16 | >40 | >65 | |||||

≤40 | ≤65 | ≤80 | ≤100 | ≤40 | ≤65 | ≤100 | |||||||

| E235 | 1.0308 | +AR ora +N | 235 | 225 | 215 | 205 | 195 | 360 | 360 | 360 | 340 | 25 | 23 |

| E275 | 1.0225 | +AR ora +N | 275 | 265 | 255 | 245 | 235 | 410 | 410 | 410 | 380 | 22 | 20 |

| E315 | 1.0236 | +AR ora +N | 315 | 305 | 295 | 280 | 270 | 450 | 450 | 450 | 420 | 21 | 19 |

| E355 | 1.0580 | +AR ora +N | 355 | 345 | 335 | 315 | 295 | 490 | 490 | 490 | 470 | 20 | 18 |

| E470 | 1.0536 | +AR | 470 | 430 | - | - | - | 650 | 600 | - | - | 17 | 15 |

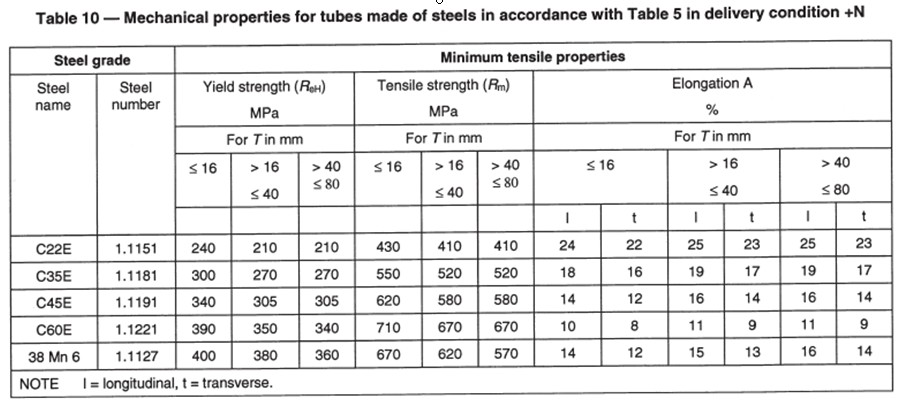

| delivery condition +N | |||||||||||||

| Steel Grade | Minimum tensile properties | ||||||||||||

| Steel name | Steel number | Yeld strength(ReH) MPa | Tensile strength(Rm) MPa | Elongation A % | |||||||||

| For T in mm | For T in mm | For T in mm | |||||||||||

| ≤16 | >16 | >40 | ≤16 | >16 | >40 | ≤16 | >16 | >40 | |||||

≤40 | ≤80 | ≤40 | ≤80 | ≤40 | ≤80 | ||||||||

| l | t | l | t | l | t | ||||||||

| C22E | 1.151 | 240 | 210 | 210 | 430 | 410 | 410 | 24 | 22 | 25 | 23 | 25 | 23 |

| C35E | 1.1181 | 300 | 270 | 270 | 550 | 520 | 520 | 18 | 16 | 19 | 17 | 19 | 17 |

| C45E | 1.1191 | 340 | 305 | 305 | 620 | 580 | 580 | 14 | 12 | 16 | 14 | 16 | 14 |

| C60E | 1.1221 | 390 | 350 | 340 | 710 | 670 | 670 | 10 | 8 | 11 | 9 | 11 | 9 |

| delivery condition +QT | delivery condition +QT | ||||||||||||||||

| Steel Grade | Minimum tensile properties | ||||||||||||||||

| Steel name | Steel number | Yield strength(ReH) Mpa | Tensile strength(Rm) Mpa | Elongation A % | |||||||||||||

| For T in mm | For T in mm | For T in mm | |||||||||||||||

| ≤8 | >8 | >20 | >50 | ≤8 | >8 | >20 | >50 | ≤8 | >8 | >20 | >50 | ||||||

≤20 | ≤50 | ≤80 | ≤20 | ≤50 | ≤80 | ≤20 | ≤50 | ≤50 | |||||||||

| l | t | l | t | l | t | l | t | ||||||||||

| C22E | 1.1151 | 340 | 290 | 270 | 260 | 500 | 470 | 440 | 420 | 20 | 18 | 22 | 20 | 22 | 20 | 22 | 20 |

| C35E | 1.1181 | 430 | 380 | 320 | 290 | 630 | 600 | 550 | 500 | 17 | 15 | 19 | 17 | 20 | 18 | 20 | 18 |

| C45E | 1.1191 | 490 | 430 | 370 | 340 | 700 | 650 | 630 | 600 | 14 | 12 | 16 | 14 | 17 | 15 | 17 | 15 |

| C60E | 1.1221 | 580 | 520 | 450 | 420 | 850 | 800 | 750 | 710 | 11 | 9 | 13 | 11 | 14 | 12 | 14 | 12 |

| delivery condition +QT | |||||||||||||||||

| Steel Grade | Minimum tensile properties | ||||||||||||||||

| Steel name | Steel number | Yield strength(ReH) Mpa | Tensile strength(Rm) Mpa | A % | |||||||||||||

| For T in mm | For T in mm | For T in mm | |||||||||||||||

| ≤8 | >8 | >20 | >50 | ≤8 | >8 | >20 | >50 | ≤8 | >8 | >20 | >50 | ||||||

| ≤20 | ≤50 | ≤80 | ≤20 | ≤50 | ≤80 | ≤20 | ≤50 | ≤80 | |||||||||

| l | t | l | t | l | t | l | t | ||||||||||

| 25CrMo4 | 1.7218 | 700 | 600 | 450 | 400 | 900 | 800 | 700 | 650 | 12 | 10 | 14 | 12 | 15 | 13 | 16 | 14 |

| 30CrMo4 | 1.7216 | 750 | 630 | 520 | 480 | 950 | 850 | 750 | 700 | 12 | 10 | 13 | 11 | 14 | 12 | 15 | 13 |

| 34CrMo4 | 1.7220 | 800 | 650 | 550 | 500 | 1000 | 900 | 800 | 750 | 11 | 9 | 12 | 10 | 14 | 12 | 15 | 13 |

| 42CrMo4 | 1.7225 | 900 | 750 | 650 | 550 | 1100 | 1000 | 900 | 800 | 10 | 8 | 11 | 9 | 12 | 10 | 13 | 11 |

Related Search

Mechanical Steel Tubing

Mechanical Tubing

Steel Tubing

316l Stainless Steel Tubing

Seamless Stainless Steel Tubing

Hydraulic Steel Tubing

More>>